Why should we pay attention to the performance of the washing machine drainage system?

Many people often ignore the importance of the washing machine drainage system, but in fact, it is a key link to ensure the long-term stable operation of the machine. If the drainage is not smooth or the pipe is aging and broken, it may cause water to overflow the floor and damage the furniture, and even cause safety hazards. Therefore, it is very important to choose a drainage pipe that is high quality and suitable for your own model.

Understanding Multifunctional Drains: The Secret of Compatibility and Flexibility

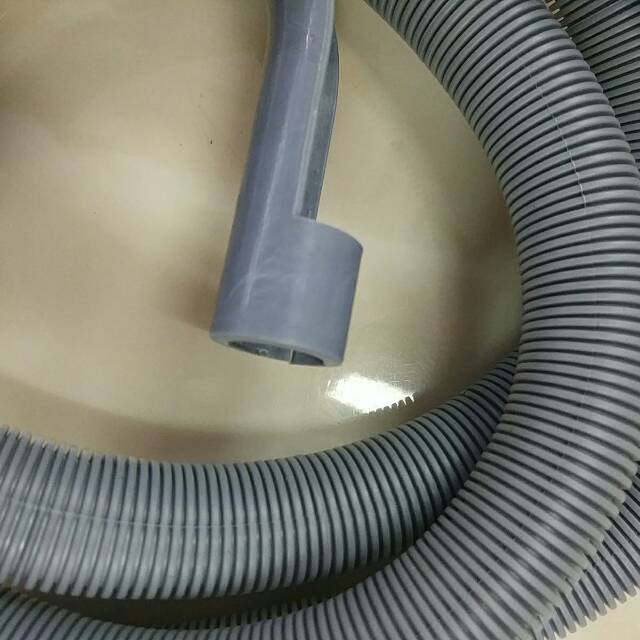

Modern life pursues convenience and speed, and this "special extension hose for sewage washing machine" is designed for this purpose. It can be widely adapted to various brands and models, including pulsator type and drum type automatic washing machines, and supports the adjustment of different heights, truly realizing the concept of "one thing with multiple uses.

Material analysis: how to choose durable and safe products

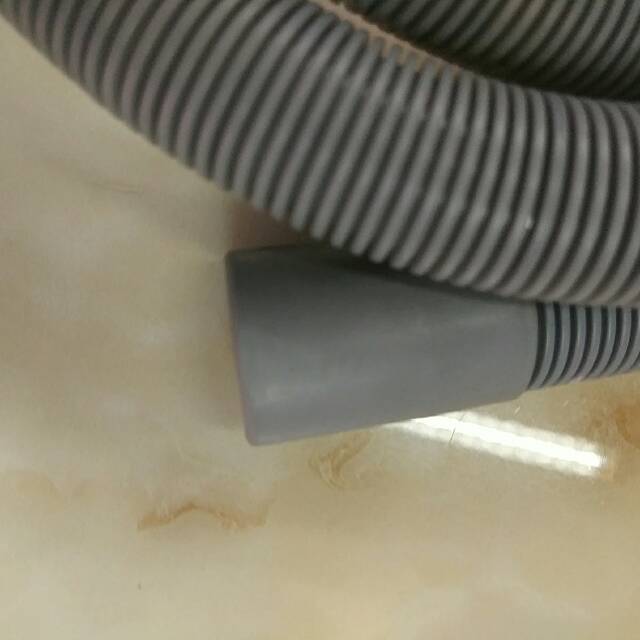

High-quality materials are one of the criteria for measuring product quality. This product is made of food grade environmental protection TPR/PVC composite film, with strong corrosion resistance and high temperature resistance and low temperature characteristics, in extreme environments still remain flexible and not easy to crack. In addition, the transparent visual window also allows users to observe the internal water flow at any time in order to find potential faults in time.

Length Adaptation Skills: Tailor-made solutions for your washing space

The location of the washing machine varies from family to family, so the standard size may not meet all needs. This series provides a variety of specifications for consumers to choose freely, with a maximum length of more than three meters sufficient to cover most application scenarios. And its own quick connector is firmly connected and easy to install and disassemble without tools.

Installation Tips: Make Replacement Easy and Pleasant

Even novices without relevant experience can complete the entire process independently. First, close the water source valve, then unplug the original old pipeline, then put the new product into the designated interface, and finally check whether the sealing ring is tight and in place before it can be put into use. The whole process takes no more than five minutes to save worry and effort.

FAQ: Ways to deal with tricky situations such as leaks or blockages

we have sorted out some practical suggestions for possible problems as follows:

if you encounter leakage phenomenon, you must first confirm whether there are signs of loosening in each joint part and then test again after tightening.

As for the blockage can be washed by hot water with a slender brush to remove foreign matter to restore the unimpeded state.

also remind you that regular maintenance helps to extend the service life and reduce the frequency of maintenance.