Why is high-quality drain pipe important? Analyzing its impact on washing machine performance

A high-performance washing machine is inseparable from a complete drainage system. Whether it is a pulsator type or a drum type washing machine, a good quality drain pipe can effectively prevent blockage and damage. Especially in the case of long-term and high-frequency use, inferior drainage pipes may cause sewage backflow or even machine failure, which seriously affects the laundry experience.

Material Competition-Which material is best for your needs?

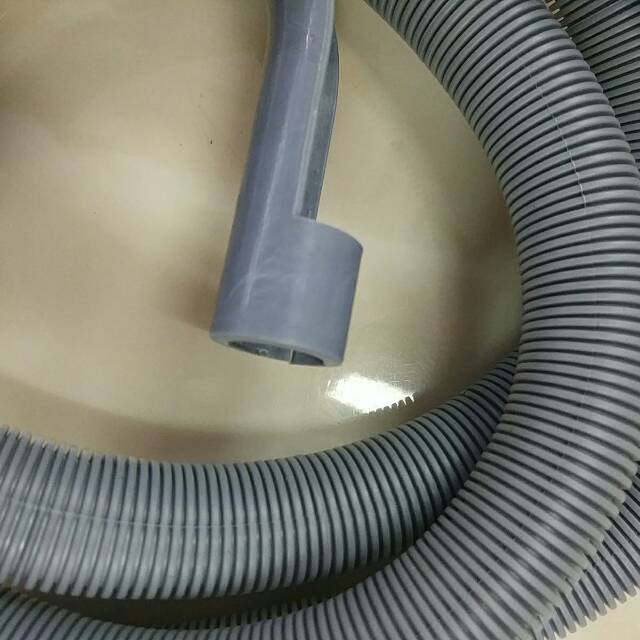

There are two main types of common drain pipes on the market: PVC plastic pipes and silicone hoses. PVC plastic pipe because of its low price, moderate hardness has become the first choice for many consumers; and silicone hose is favored by virtue of its stronger flexibility and anti-aging ability. The choice can be based on the actual application scenario and personal budget to make a trade-off.

Size is no small matter-teach you to measure correctly and choose the right length

Determining the appropriate drain length is an important step to ensure a smooth installation. In general, we need to reserve enough extension space to connect to the floor drain or external drain. It is recommended to measure the linear distance from the bottom of the washing machine to the designated drain position, and add at least 30cm as a safety margin on this basis.

DIY talent must see! Simple steps to complete the professional installation process

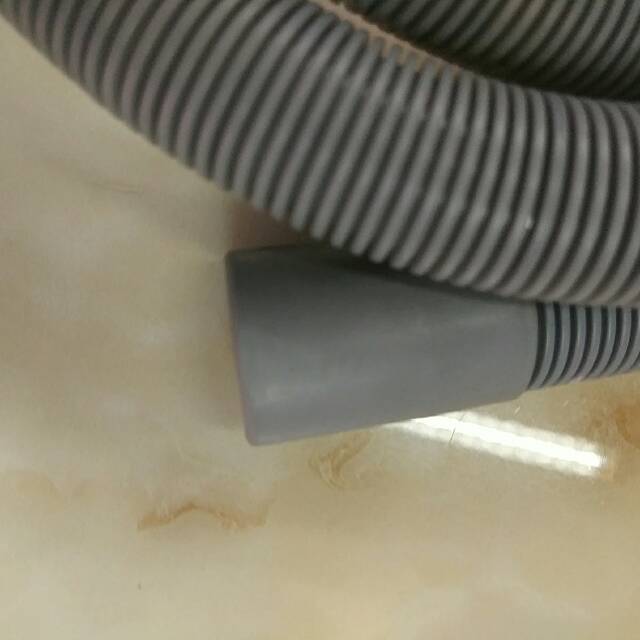

Replacing the drain is not as complicated as you think. After first turning off the power and disassembling the original components, the newly purchased pipe is cut to the appropriate size according to the mark, and then firmly fixed at its outlet to be put into use. Remember to check whether the interface is well sealed to put an end to the hidden danger of water leakage!

Common Mistakes Warning Record-Don't Let Wrong Habits Shorten Product Life

Although high-quality drainage pipes have a long service period, they may be damaged in advance if they are not properly maintained. For example, long-term excessive bending will cause local stress concentration and thus lead to cracking risk; In addition, neglect of cleaning work will allow residue accumulation to form a blocking point. Regular dredging and maintaining a reasonable placement can greatly delay the aging process.